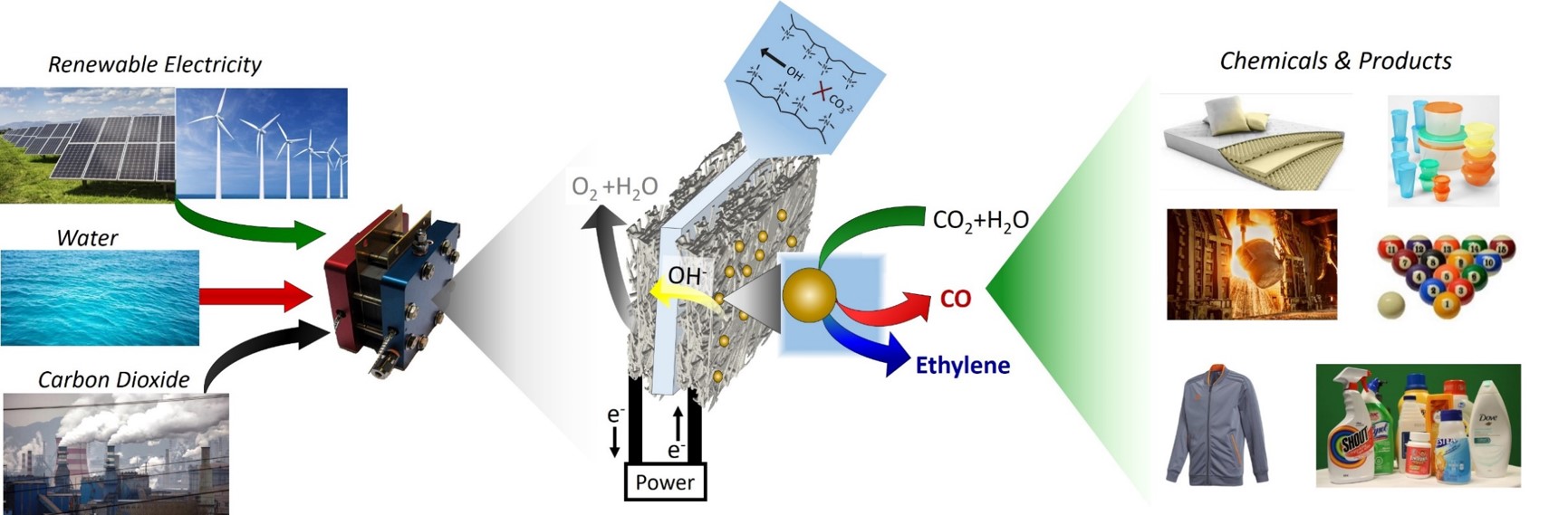

- I am currently a full professor in the Surface Science and Catalysis section at the Physics Department at the Technical University of Denmark (DTU). Our research focuses on using the power derived from sustainable energy sources (i.e. wind and solar) and using this to electrochemically drive reactions to high value chemicals and fuels. I am heavily involved in the Villum Center for Sustainability (VSustain) and the Pioneer Center for Accelerating P2X Materials Discovery (CAPeX) , thus a significant amount of my research is tied in to the focus of this center as well. To contact me my email is brse@dtu.dk.

-

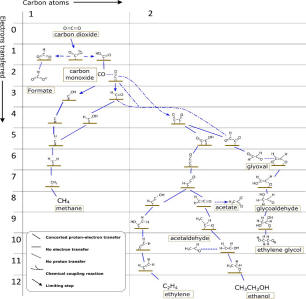

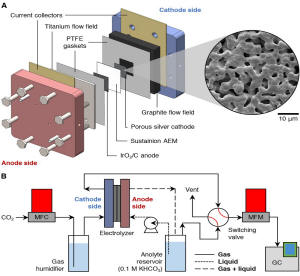

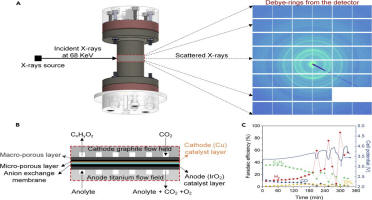

- My research is focused on accelerating the transition from a fossil fuel and chemical based society to one that is based on sustainable energy and chemicals. To understand where we are now, and where we need to be, see my powerpoint I use for the introductory lecture to my Physics of Sustainable energy course here. Into the details, my research relates to various electrocatalytic reactions primarily related to CO2 electrolysis to various organic chemicals (see motivation), but also including water electrolysis and partial oxidation reactions.

-

- My

research can be broken down into various forms of

electrocatalysis both in terms of reductive reacitons,

oxidative reactions, and electrochemical device analysis.

Click on one of the links below to learn more about one

these focuses.

|

Seger Research |

|